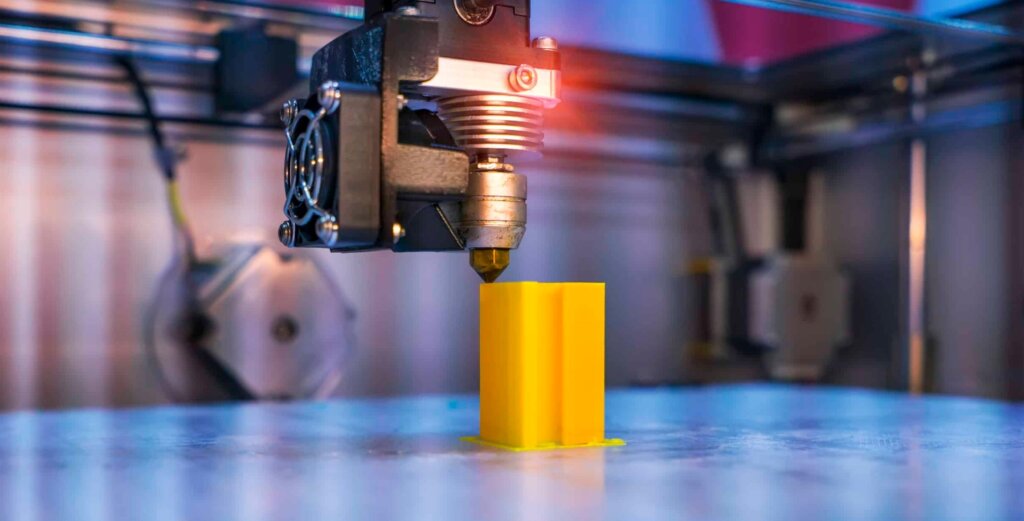

Additive manufacturing, commonly termed 3D printing, is an astonishing breakthrough that is altering assembly procedures. Dissimilar to revolutionary assembly approaches, which entail removing material from a block of unrefined substance, added substance fabricating creates items layer by layer, adding material till the right form is completed. This remarkable approach offers a large number of benefits, making it a vital gadget for distinct firms.

Releasing the Capability of Additive Manufacturing

At the foundation of additive manufacturing resides the potential to offer intricate computations that would be challenging or tough to create utilizing conventional approaches. This capacity brings up a universe of alternatives for producers and designers, permitting them to build creative goods with improved usefulness, further expanded execution, and reduced weight.

Additive Manufacturing: Unveiling a World of Benefits

Additive manufacturing, also called 3D printing, has developed as an amazing power in the assembly scene, revolutionizing traditional creation methods with its outstanding layer-by-layer approach.

Not at all like subtractive manufacturing, which requires deleting material from a sturdy block, additive manufacturing produces items by carefully retaining material, requiring mind-boggling calculations that are tough to achieve. This inventive invention opens a heap of advantages, pushing it to the very front of contemporary assembly.

1. Improved Design Opportunity: Additive manufacturing frees originators from the imperatives of conventional assembling, opening doors to an area of massive plan potential.

The ability to provide many-sided forms and intricate computations that were previously out of reach enables planners to liberate their imagination, prompting the creation of imaginative goods with improved usefulness, further expanded execution, and reduced weight. This design change cultivates a culture of development, encouraging the creation of significant products that push the bounds of what’s possible.

2. Decreased Material Waste: Maintainability has changed into a major worry in the current assembly atmosphere and additive manufacturing stands alone as a boss of asset protection. By creating items layer by layer, additional substance creation fundamentally lessens material waste contrasted with subtractive strategies that dispose of an excess of material throughout the machining technique. This eco-accommodating approach restricts natural effect, aligning with the increasing interest in maintainable assembly rehearses.

3. Facilitated Prototyping and Customization: Additive manufacturing has revolutionized the prototype procedure, permitting experts to generate genuine models of their designs for testing and assessment swiftly. This iterative contact, filled by speedy prototyping, speeds up item improvement and reduces time to display, providing firms an upper hand. Moreover, additive manufacturing works with mass customization, taking into mind the development of innovative and personalized things on request, taking special care of the rising client propensity for individualized items.

4. Releasing Manufacturing Effectiveness: Additive manufacturing smoothest assembly operations, leading to major increases in productivity. The capacity to offer sophisticated computations without the requirement for specialized tooling or shape kills the protracted and pricey arrangement timeframes associated with typical assembly approaches. Besides, extra substance permits the solidification of many pieces into a solitary portion, lessening gathering time and complexity. This proficiency increases transfer into lowered creation costs and further developed item quality.

5. Engaging Development Across Businesses: The cutting-edge power of additive manufacturing expands across different enterprises, changing objects and upgrading and gathering systems in numerous fields. In the aerodynamic exchange, additional substance creation works with the creation of lightweight, high-strength components for planes and space gear, bringing down fuel usage and supporting execution.

The automotive organization welcomes more substance gathering to manufacture lightweight, strong, and confused parts for vehicle bodywork, motors, and interior segments, intending for eco-accommodating and innovative autos. In the medical care region, additional substance manufacturing is altering patient concerns by permitting the construction of updated ads, prostheses, and wary gadgets, dealing with figuring out results and driving clinical medications.

Unveiling the Diverse Applications of Additive Manufacturing

Additive manufacturing has appeared as an outstanding innovation with vast applicability throughout a wide selection of undertakings. Dissimilar to usual assembly procedures that entail deleting material from a strong block, additive manufacturing creates items layer by layer, adding material till the correct form is completed. This innovative process opens a horde of advantages, driving it to the very front of contemporary assembling.

Aerospace: Taking off Higher than ever using Additive Manufacturing

In the aerospace trade, additive manufacturing has altered the strategy and development of lightweight, superior execution parts. The potential to give many-sided computations without the limits of typical assembly has allowed architects to design unique airplane parts that were previously unachievable.

Fuel-efficient components: Additive manufacturing has enabled the creation of lightweight, high-strength parts for aircraft and shuttles, decreasing fuel utilization and enhancing execution. For example, additively created sections and underlying parts might entirely lessen the general burden of an airplane, motivating further developed eco-friendliness and widened range.

Complex geometries: Additive manufacturing has involved the manufacture of sophisticated computations that would be trying or tough to make utilizing usual techniques. For instance, additively built fuel injectors might feature complicated inner channels and computations that simplify fuel stream and ignition productivity.

Reduced lead times: Additive manufacturing smoothes out the creation cycle by wiping out the demand for particular tools or forms, fundamentally lowering lead times for aircraft parts. This rapid prototyping capacity speeds up item advancement and gives innovative concepts for sale to the public swiftly.

Automotive: Driving Development with Additive Manufacturing

The automobile sector has adopted additive manufacturing to manufacture lightweight, sturdy, and sophisticated parts for car bodywork, motors, and internal parts. This invention is made ready for eco-friendly and innovative autos.

Weight reduction: Additive manufacturing empowers the development of lightweight parts, leading to generally speaking vehicle weight decrease and improved eco-friendliness. For example, additively made car parts can be planned with many-sided grid structures that deliver strength and inflexibility while minimizing weight.

Custom components: Additive manufacturing works with the development of remade parts custom-fitted to precise vehicle prerequisites. This feature is notably vital for elite execution vehicles and dashing vehicles, where streamlined elements can boost execution and deal with.

Prototype and testing: Additive manufacturing supports prototype and testing cycles in the automotive sector, permitting architects to swiftly examine plan concepts and make crucial improvements before resolving large-scale manufacture. This iterative process minimizes progress time and cost.

Clinical Gadgets: Improving Patient Consideration with Additive Manufacturing

Additive manufacturing is transforming the clinical area by empowering the manufacture of customized inserts, prosthetics, and cautious tools, working on silent outcomes, and driving clinical drugs.

Personalized implants: Additive manufacturing involves the fabrication of patient-explicit inserts that indisputably match individual living structures and needs: this personalized method prompts further developed embed fit, lessens the danger of perplexity, and enhances patient comfort.

Complex prosthetics: Additive manufacturing facilitates the construction of diverse prostheses that counterfeit ordinary human life systems and development. This capacity provides patients with more prominent utility, more developed mobility, and a restored sensation of independence.

Surgical instruments: Additive manufacturing works with the development of remade cautious tools specially suited to explicit methods. This accuracy boosts attentive exactness, reduces tissue injury, and works on durable outcomes.

Purchaser Merchandise: Customizing Items using Additive Manufacturing

Additive manufacturing is revolutionizing the purchaser merchandise sector by permitting the development of remarkable and personalized things on request. This innovation is offering up new pathways for progress and originality in item creation.

Customized products: Additive manufacturing takes into consideration the manufacture of customized goods custom-made to individual preferences and wants. This skill is especially crucial for fashion accessories, jewelry, and other personal objects.

Small-batch production: Additive manufacturing allows the creation of tiny bunches of products, taking particular care of niche marketplaces and unique customer requirements. This versatility is especially helpful for firms who need to provide redid goods without the aforesaid large-scale production.

Additive manufacturing material fabricating improves prototype cycles for customer merchandise, letting creators test and refine item concepts before committing resources to large-scale manufacture swiftly. This iterative process minimizes improvement time and expense.

The Future of Additive Manufacturing: A Transformative Force

Additive manufacturing also termed 3D printing, has emerged as an amazing innovation with the opportunity to change fabricating cycles and item designs across a broad variety of organizations. Dissimilar to usual assembly procedures that entail reducing material from a strong block, Additive manufacturing fabricates items layer by layer, adding material till the correct form is completed. This remarkable approach offers a heap of advantages, bringing it to the front of present-day production.

Key Drivers of Additive Manufacturing Growth

The adoption of AM is being pushed by a few significant aspects, including:

Technological advancements: Nonstop progressions in Additive manufacturing innovations, for example, further developed objectives, quicker construct speeds, and more extensive scope of materials are expanding the capabilities and utilization of AM.

Reduced costs: As AM innovations advance and creation volumes increment, the expense of AM is intended to decline, making it more open to a more extensive scope of organizations.

Developing interest in customization: AM’s capacity to supply changed and personalized things are taking care of the developing purchaser’s demand for unique and individualized products.

Sustainability considerations: AM’s material-effective and waste-reducing character lines up with the expanding accentuation on reasonable assembly rehearses.

Arising Trends in Additive Manufacturing

- A few emergent tendencies are sculpting the future of AM:

Multi-material AM: The capacity to integrate various materials within a single AM procedure opens up additional alternatives for item plan and usefulness.

Consistent AM: Progressions in persistent Additive manufacturing strategies, for example, electron beam melting (EBM), are empowering the construction of huge scope, superior execution metal components.

AM in big-scale production: AM is gradually being coordinated into large-scale manufacturing lines, notably for redid goods and low-volume fabrication runs.

Hybrid manufacturing: AM is being combined with traditional assembling strategies to produce crossover fabricating methods that affect the characteristics of the two methodologies.

Effect of Additive Manufacturing on Enterprises

AM is set to have a huge influence on numerous industries, including:

Aviation: AM is boosting the creation of lightweight, high-strength components for airplanes and space equipment, reducing fuel utilization and upgrading execution.

Auto: AM deals with the creation of lightweight, robust, and sophisticated parts for car bodywork, engines, and inner parts, making them ready for eco-friendly and imaginative automobiles.

Medical devices: AM is revolutionizing the clinical sector by empowering the production of modified inserts, prosthetics, and cautious tools, working on silent outcomes, and driving clinical medications.

Consumer goods: AM is revolutionizing the client products business by empowering the production of one-of-a-kind and personalized things on request, opening up new roadways for improvement and inventiveness in item design.

Future Standpoint for Additive Manufacturing

The future of AM is superb, having the opportunity to modify companies and disturb how we configure, create, and utilize products. As AM innovations keep on expanding, prices fall, and applications extend, AM is intended to assume an unquestionably unmistakable position in the assembling scene. AM can open new degrees of development, effectiveness, and customization, altering the universe of assembly into the indefinite future.

Key Difficulties and Contemplations

Despite its bright future, AM encounters clear obstacles and contemplations that need to be cared of for its broad reception:

Standardization: The absence of standardization among AM developments and materials might obstruct more broad reception and interoperability.

Quality confirmation: Guaranteeing predictable and consistent quality control is crucial for AM-created components, particularly in basic applications.

Education and training: Expanding knowledge and training regarding AM breakthroughs and applications is vital for labor force improvement and reception.

Cost contemplations: While AM expenses are anticipated to decline, commencing interest in AM hardware and supplies might be significant.

Tending to these issues and contemplations will prepare for the inevitable reception of Additive Manufacturing and its exceptional influence on diverse ventures and society overall.