- What is An Anti Lock braking system (ABS)?

An Anti Lock braking system (ABS) is a security framework that stops the wheels of a vehicle from Locking up and sliding when the brakes are applied. This is significant on the grounds that when the wheels secure, the driver fails to keep a grip on the vehicle and it can slip into an impediment or off the pavement.

Anti Lock braking system (ABS) operates by applying sensors to screen the speed of each wheel. In the event that a wheel is going to secure, the Anti Lock braking system (ABS) regulator lessens the braking strain on that wheel. This lets the wheel keep pivoting and keep up with the footing of the street. The Anti Lock braking system (ABS) regulator beats the braking strain to the wheel a few times each second, which is the reason you can sense a throbbing sensation in the brake pedal when the Anti Lock braking system (ABS) is activated.

Advantages of Anti Lock braking system (ABS)

Anti Lock braking system (ABS) has several advantages, including:

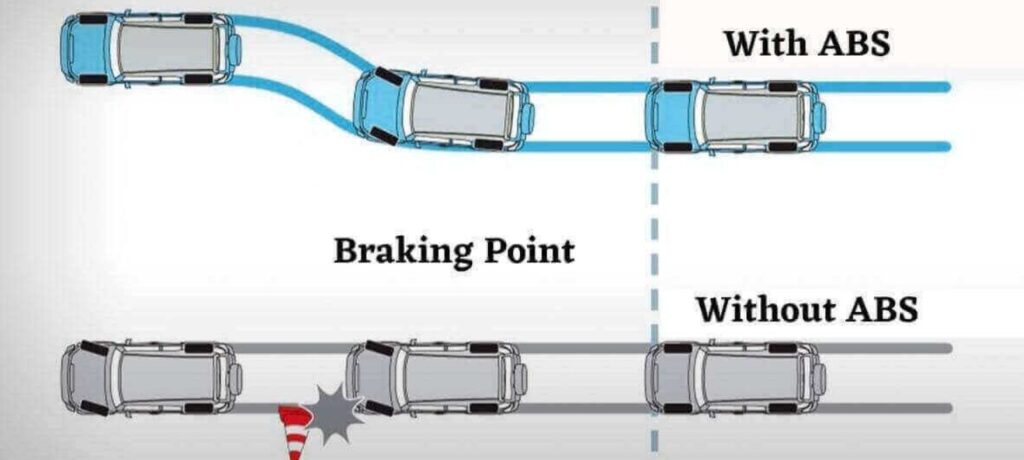

Reduced stopping lengths: Anti Lock braking system (ABS) can assist with decreasing halting distances on slippery surfaces, like wet or ice roads.

Improved steering control: Anti Lock braking system (ABS) helps the driver to keep up with guiding control of the car in any circumstance, despite slowing down aggressively.

Decreased hazard of mishaps: Anti Lock braking system (ABS) might assist with lessening the chance of mishaps brought on by slippage.

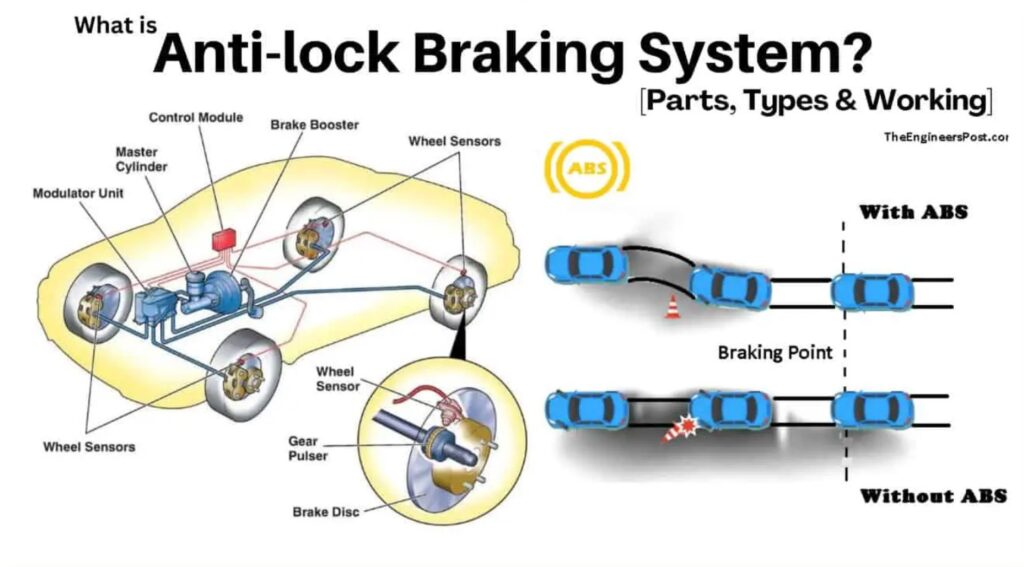

- How Anti Lock Braking System (ABS) Functions:

ABS works by utilizing many elements, including:

Wheel speed sensors: These sensors screen the speed of each wheel.

ABS controller: This controller collects signals from the wheel speed sensors and controls the stopping mechanism.

Hydraulic valves: These valves control the brake tension to each wheel.

At the instant that the driver applies the brakes, the ABS controller screens the speed of each wheel. Assuming a wheel is going to secure, the ABS regulator decreases the braking effort to that wheel. This lets the wheel keep turning and keep up with the foothold of the street. The ABS controller beats the brake strain to the wheel a few times per second, which is the reason you can sense a throbbing sensation in the brake pedal when ABS is enacted.

- ABS Limitations

ABS is an incredibly powerful security framework, yet it is critical to mind that it includes a few constraints.

ABS may not be successful on all surfaces: ABS is best on hard, smooth surfaces. On free or lopsided surfaces, ABS will be unable to keep the wheels from securing.

ABS may not shorten stopping distances on all surfaces: On dry, clean surfaces, ABS may not shorten stopping distances on all surfaces

ABS could force the driver to change their slowing down method: Drivers who are curious about ABS might have to change their slowing down procedure when ABS is deployed.

- ABS and Foothold Control Frameworks

ABS is usually combined with a foothold control framework (TCS). TCS is a security framework that assists with keeping the wheels of a vehicle from losing foothold and turning while speeding up. ABS and TCS cooperate to work on the taking care of and wellness of autos.

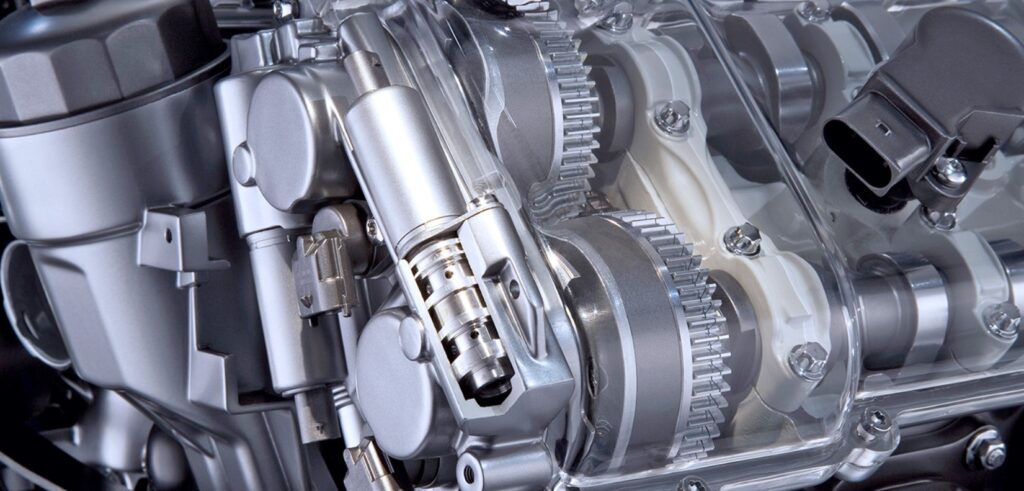

Variable Valve Timing Solenoid (VVTs) and Their Relationship to Anti-Lock Braking System (ABS)

Variable Valve Timing Solenoid (VVTs) is an engine technology that lets the engine’s computer to vary the planning of the valves to boost execution and efficiency. Variable Valve Timing Solenoid are electrical parts that govern the oil stream to the Variable Valve Timing Solenoid actuators, which really vary the planning of the valves.

The ABS is a wellness framework that protects the wheels of a car from fastening and sliding when the brakes are employed. ABS works by applying sensors to screen the speed of each haggle the braking strain to that wheel.

Variable Valve Timing Solenoid and the ABS are not directly related, yet they can share a few elements. For instance, the ABS wheel speed sensors might be utilized to communicate messages to the engine’s computer. These indicators can be utilized to manage the VVT solenoids and advance motor execution.

At times, breaking down Variable Valve Timing Solenoid can present some complications with the ABS. For instance, on the off chance that a VVT solenoid is jammed, it can make the motor perform ineffectively and the ABS framework to break down.

- Side Consequences of a Failing Variable Valve Timing Solenoid

There are a couple of adverse effects that could suggest a breaking down VVT solenoid, including:

Check engine light: The check engine light could turn on in the event that the engine’s computer finds a fault with the VVT system.

Rough idle: The engine can sit harshly or vibrate on the off chance that the Variable Valve Timing Solenoid is not performing as planned.

Reduced power: The engine can have diminished power on the odd chance that the VVT solenoids are not performing as planned.

Expanded fuel usage: The motor can have expanded fuel utilization on the off chance that the Variable Valve Timing Solenoid are not performing as planned.

- Reasons for a Failing Variable Valve Timing Solenoid

Various variables can make a Variable Valve Timing Solenoid malfunction, including:

Oil sludge: Oil sludge can build on the VVT solenoids and impede them from working effectively.

Electrical difficulties: Electrical faults, like a blown circuit or a wrecked wire, can hinder the VVT solenoids from working effectively.

Mechanical harm: Mechanical harm to the VVT solenoids, for example, from a crash, can keep them from working effectively.

- Determination and Fix of a Breaking down VVT Solenoid

A failing Variable Valve Timing Solenoid can be investigated by an ensured professional utilizing an indicating scanner. The technician will actually want to test the VVT solenoids and assess whether they are performing adequately. In the event that the VVT solenoids are not operating as envisioned, they should be substituted.

- Avoidance of Variable Valve Timing Solenoid Issues

There are a couple of things that should be possible to prevent Variable Valve Timing Solenoid difficulties, including:

Regular oil changes: Regular oil changes can assist with keeping oil muck from developing on the VVT solenoids.

Regular maintenance: Customary upkeep, for example, check ups and investigations, can assist with recognizing and right electrical difficulties or mechanical harm that could create VVT solenoid troubles.

Avoid hard driving: hard driving, for example, pounding on the brakes or firing up the motor high, can place weight on the VVT solenoids and influence them to breakdown.

Purge Valve Solenoid and Its Relationship to Anti-Lock Braking System (ABS)

- What is a Purge Valve Solenoid?

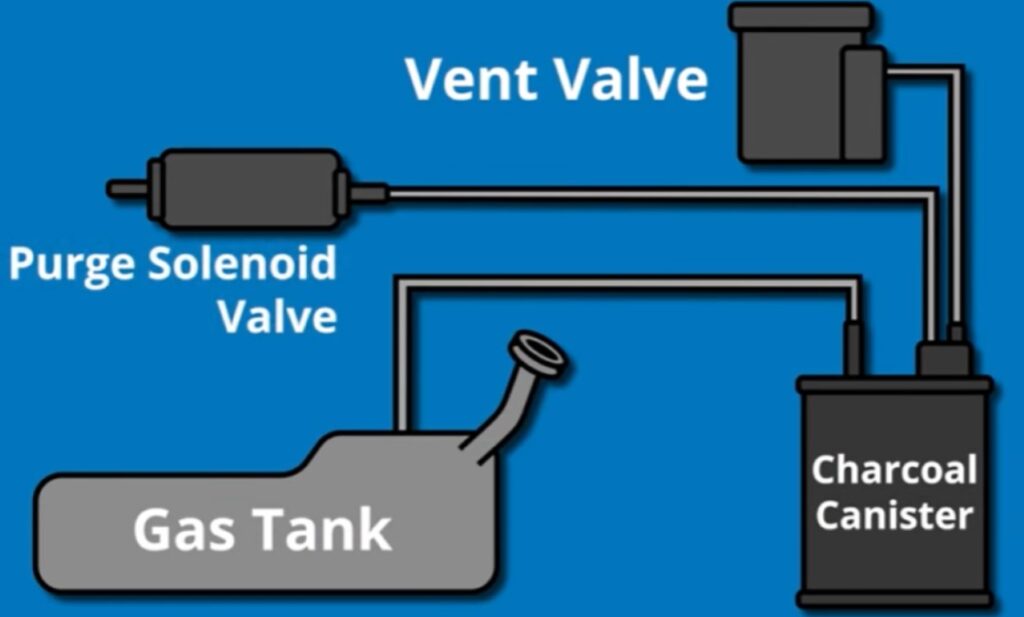

A Purge valve solenoid, otherwise called an EVAP Purge solenoid valve, is a crucial part in the Evaporative Emission Control System (EVAP) of modern automobiles. It is answerable for managing the progression of fuel fume from the charcoal canister to the motor’s admission complicated throughout motor activity.

How does the purge valve solenoid work?

At the point when the motor is operating and the EVAP framework is started, the purge valve solenoid opens to permit fuel vapor from the charcoal canister to stream into the admission complex. The motor then eats this vapor, keeping it from being transported into the climate. The purge valve solenoid is constrained by the Engine Control Module (ECM), which filters distinct motor boundaries and opens the valve when the circumstances are suitable.

Relationship with the Anti-Lock Braking System (ABS)

- The purge valve solenoid with the Anti-Lock Braking System (ABS)

Three are two free frameworks that work in diverse regions of the automobile. The fundamental capability of the ABS is to forestall wheel Lockup and sliding when slowing down, while the purge valve solenoid monitors fuel vapor discharges.

In any event, there is a potential backhanded relationship between the two frameworks. In certain vehicles, the ABS wheel speed sensors might be employed to give a contribution to the ECM, which might effect the operation of the purge valve solenoid. For example, in the event that the ABS sensors notice an unanticipated change in wheel speed, the ECM could briefly impair the purge valve solenoid to zero in on keeping up with vehicle security and forestalling sliding.

Symptoms of a Failing Purge Valve Solenoid

A failed purge valve solenoid might induce several side effects, including:

Illuminated Check Engine Light: The ECM might set off the Check Engine Light presuming that it identifies an issue with the cleanse valve solenoid’s activity.

Engine Misfire: Assuming the cleanse valve solenoid opens at incorrect times, it can send excessive fuel fume into the admission complex, creating motor failures to fire and harsh inactivity.

Expanded Fuel Utilization: The ill-advised activity of the cleanse valve solenoid can bring in wasteful fuel fume cleansing, prompting expanded fuel utilization.

Strong Fuel Odor: A breaking down cleanse valve solenoid can permit fuel fume to escape into the atmosphere, generating areas of strength for a smell surrounding the car.

- Diagnosis and Repair of a Malfunctioning Purge Valve Solenoid

Diagnosing a breaking down purge valve solenoid typically contains utilizing a symptomatic scanner to check for issue codes connected with the EVAP Purge Valve Solenoid framework. The expert will then evaluate the Purge valve solenoid for any genuine harm or electrical difficulties. On the off chance that the solenoid is considered as defective, it should be supplanted.

- Counteraction of Purge Valve Solenoid Issues

To assist with forestalling purge valve solenoid troubles, it is crucial to follow the suggested support strategy for your vehicle, which can encompass standard assessments and substitution of the charcoal canister or purge valve solenoid on a case by case foundation. Furthermore, staying away from extra fuel packing and utilizing clean fuel from trustworthy suppliers might minimize the chance of pollutants impacting the EVAP purge valve solenoid framework parts

Service Traction Control Chevy Cruze: A Comprehensive Guide

The “Service Traction Control” warning in your Chevy Cruze signals a breakdown in the vehicle’s traction control system. This system, also termed Electronic Stability Control (ESC), operates connected to the Anti-Lock Braking System (ABS) to keep up with vehicle soundness and forestall slides throughout speed increases, cornering, and perplexing street circumstances.

Potential Reasons for the “Service Traction Control” Message

A few elements can set off the “Service Traction Control” notification in your Chevy Cruze. These include:

Faulty Wheel Speed Sensors: Wheel speed sensors screen the rotational speed of each wheel, delivering crucial information to the foothold control framework. In the event that at least one sensor are breaking down, the framework may not receive exact wheel speed data, prompting a blunder message.

Problematic ABS Wheel Hub Assemblies: The ABS wheel center point gatherings house the wheel speed sensors and orientation. On the off chance that the center point gathering is hurt or worn, it can affect the sensor’s exhibition and prompt the foothold control cautioning.

Faulty Yaw Rate Sensor: The yaw rate sensor evaluates the vehicle’s pivot around its upward hub, supplying data about the vehicle’s stability. A failed yaw rate sensor can disturb the foothold control framework’s capacity to notice and answer changes in vehicle elements.

Steering Angle Sensor Issues: The steering angle sensor tracks the angle of the steering wheel, letting the foothold control framework to in like manner adjust its mediation. A malfunctioning steering angle sensor can deliver inaccurate information, prompting the footing control warning.

Electrical difficulties: Electrical difficulties, like free associations, harmed wiring, or blown wires, can disrupt the correspondence between the foothold control framework pieces, setting off the blunder message.

Programming Issues: now and again, programming faults or outmoded programming renditions can cause the foothold control framework to glitch. Refreshing the vehicle’s product might determine the issue.

Steps to Address the “Service Traction Control” Message

In the event that the “Service Traction Control” notice shows up on your Chevy Cruze’s instrument display, making the accompanying strides is suggested:

Switch Off and Restart the Engine: Some of the time, a simple restart can clear impermanent problems in the footing control framework.

Check for Free Associations or Harmed Wiring: Investigate the wiring and connectors linked with the foothold control framework for any indications of harm or detachment.

Clean Wheel Speed Sensors: Soil or rubbish growth on the wheel speed sensors might slow down their activity. Clean the sensors delicately with a sensitive brush or condensed air.

Check Tire Pressure: Guarantee all tires are suitably expanded to the prescribed pressure levels. Inappropriate tire strain can influence the framework’s capacity to keep up with footing.

Seek Professional Diagnosis: In the event that the blunder message perseveres following these basic tests, it is prudent to have the vehicle analyzed by a certified technician. They can utilize unique equipment and demonstrated tactics to determine the particular reason for the malfunction and recommend correct repairs.

Preventive Measures to Traction Control Issues

- To help prevent future traction control issues, try the following:

Regular Maintenance: Follow the recommended upkeep plan for your Chevy Cruze, which incorporates usual exams and substitutes of significant parts depending on the situation.

Avoid Harsh Driving: Stay away from fast acceleration, hard slowing down, and violent cornering, as these maneuvers might overburden the traction control framework.

Maintain Proper Tire Condition: Guarantee your tires are in wonderful form, with sufficient track profundity and legitimate filling levels.

Address Electrical troubles Immediately: Any electrical troubles ought to be remedied swiftly to protect them from influencing the foothold control system.

Keep Software Up to Date: Check for and introduce any acceptable programming updates for your Chevy Cruze’s control frameworks.

By adhering to these regulations, you may aid with keeping up with your Chevy Cruze’s traction control system and boost your vehicle’s solidness and security out and about.

Wheel Speed Sensor: An Extensive Guide

- What is a Wheel Speed Sensor?

A wheel speed sensor (WSS) is a vital feature of a cutting edge vehicle’s non-freezing stopping mechanism (ABS) and footing control framework (TCS). A small electromagnetic gizmo estimates the rotational speed of each wheel. This data is subsequently transported off the Electronic manage Unit (ECU), which utilizes it to manage the ABS and TCS frameworks.

How Does a Wheel Speed Sensor Work?

A WSS normally comprises of an appealing pickup and a toothed wheel. As the wheel turns, the teeth on the wheel pass near the pickup, producing a voltage signal. The frequency of this sign is related to the wheel’s speed. The ECU gets this sign and decides the wheel’s speed.

What are the Side effects of a Defective Wheel Speed Sensor?

A broken wheel speed sensor can create several complications, including:

The ABS or TCS light could come on: This is the most well-known side consequence of a broken WSS.

The vehicle might slip or slide: This can happen on the grounds that the ABS or TCS framework isn’t performing as planned.

The speedometer may not work: The speedometer needs on input from the WSS to effectively work.

- The amount Does a Wheel Speed Sensor Cost?

The expense of a wheel speed sensor can differ depending upon the make and type of the vehicle. Nonetheless, the average expenditure is probably in the range of $50 and $100.

The most effective approach to Supplant a Wheel Speed Sensor

Supplanting a wheel speed sensor is a reasonably evident cycle. In any event, it is necessary to scrupulously follow to the guidelines in your vehicle’s maintenance manual. As a rule, the means engaged with supplanting a WSS are:

- Lift the vehicle and delete the wheel.

- Find the WSS on the wheel center point or brake caliper.

- Disengage the electrical connector from the WSS.

- Unbolt the WSS from the wheel center or brake caliper.

- Introduce the new WSS.

- Reinstall the haggle of the vehicle.

- Ways to Prevent Wheel Speed Sensor Issues

- There are a couple of things you may do to prevent wheel speed sensor concerns, including:

Routinely wash your vehicle: This will assist in eliminating soil and flotsam and jetsam that could accumulate on the WSS and slow down its operation.

Review the WSS routinely: Search for evidence of harm, like breaks or consumption.

Supplant the WSS in the case that it is harmed: Don’t attempt to fix an injured WSS.

By following these guidelines, you can aid with preserving your wheel speed sensors all ready and prevent troubles not too far off.

Hydraulic Pump: Its Role in Anti-Lock Braking Systems

Anti-Lock braking systems (ABS) are key safety components in present day autos, forestalling wheel Locking and skids throughout slowing down. A significant aspect of Anti-Lock braking systems (ABS)is the water powered siphon, which creates the water driven pressure needed to work the ABS framework.

- Kinds of Hydraulic Pumps: Hydraulic pumps arrive in diverse kinds, although two fundamental classifications are pertinent to ABS: Gear Pumps and Vane Pumps.

Gear Pumps: Gear Pumps use gears to transport liquid inside a fixed chamber. They are noted for their straightforwardness and uncompromising quality.

Vane Pumps: Vane Pumps utilize vanes that pivot inside a chamber, forcing liquid out to produce pressure. They are by and large more reduced and effective than gear Pumps.

12 Volt Hydraulic Pump

12 volt Hydraulic Pump are explicitly intended for use in automobiles with 12-volt electrical systems. They are generally controlled by an electric engine and are in many cases relatively minimal, making them perfect for coordinating into ABS frameworks.

Dump Trailer Hydraulic Pump

Dump Trailer Hydraulic Pump are intended for heavy duty tasks, such raising and putting down dump trailers. They are generally more remarkable and durable than hydraulic pumps utilized in ABS setups.

Hydraulic Pump for Log Splitter

Hydraulic Pump for Log Splitter are utilized to control the hydraulic cylinders that split logs. They are generally high-pressure pumps that can supply the power expected to divide even the most difficult logs.

- Role of Hydraulic Pump in ABS

In an ABS framework, the Hydraulic Pump generates the pressure driven pressure expected to control the brake calipers. At the instant that the driver applies the brakes, the ABS regulator decides whether a wheel is going to secure. Provided that this is genuine, the ABS regulator communicates a message to the hydraulic pump to reduce strain to that wheel, preventing it from securing. This cycle lets the wheel to maintain up with footing and assists the vehicle with keeping up with security throughout slowing down.

Factors Influencing Hydraulic Pump Execution

A few variables can alter the display of a Hydraulic Pump in an ABS architecture, including:

Pump type: The sort of Pump employed (stuff or vane) can impact its performance, noise level, and life expectancy.

Pump size: The size of the Pump defines its ability to produce hydraulic pressure.

Operating conditions: The pump’s appearance can be altered by elements like temperature, vibration, and fluid viscosity.

- Maintaining Hydraulic Pump Health

Customary upkeep is vital to ensure the hydraulic pump in an ABS framework performs effectively. This incorporates:

Checking fluid level and condition: Standard inspections verify the hydraulic fluid is at the proper level and liberated from contaminants.

Replacing filters: Filters reduce contaminants from the hydraulic fluid liquid, shielding the pump and different parts.

Inspecting for leaks: Breaks can cause strain misfortune and reduced pump execution.

Adhering to service intervals: Following the maker’s suggested administration spans assures appropriate maintenance and broadens the pump’s lifespan.

Outline

Anti-Lock braking system (ABS)

An Anti-Lock braking system (ABS) is a safety mechanism that keeps the wheels of a vehicle from securing and skidding when the brakes are applied. This is essential in light of the fact that when the wheels secure, the driver fails to keep a grasp on the vehicle and it can slip into an object or off the pavement.

ABS works by leveraging sensors to check the speed of each wheel. On the off chance that a wheel is going to secure, the ABS regulator lessens the brake strain on that wheel. This lets the wheel to keep turning and keep up with the foothold of the street. The ABS regulator beats the brake strain to the wheel a few times each second, which is the reason you can sense a throbbing sensation in the brake pedal when ABS is enacted.

Variable valve timing solenoid (VVT solenoid)

Variable valve timing (VVT) is an engine technology that lets the engine’s computer modify the planning of the valves to increase execution and mileage. Variable valve timing solenoid are electrical parts that govern the oil stream to the VVT actuators, which really change the planning of the valves.

Purge valve solenoid

A cleanse valve solenoid, otherwise termed an EVAP Purge solenoid valve, is a crucial feature in the Evaporative Emission Control Framework (EVAP) of modern cars. It is answerable for managing the progression of fuel vapor from the charcoal canister to the motor’s admission complicated throughout motor activity.

Wheel speed sensor

A wheel speed sensor (WSS) is a basic feature of a cutting-edge vehicle’s electronically monitored slowing mechanism (ABS) and footing control framework (TCS). A small electromagnetic gizmo estimates the rotational speed of each wheel. This data is subsequently transported off the Electronic Manage Unit (ECU), which utilizes it to manage the ABS and TCS frameworks.

Hydraulic pump

A Hydraulic pump is a gadget that transforms mechanical energy into a Hydraulic pump.

I trust this is useful! Inform me if you have any more inquiries.